EVAPORATIVE COOLING

PAD SYSTEM

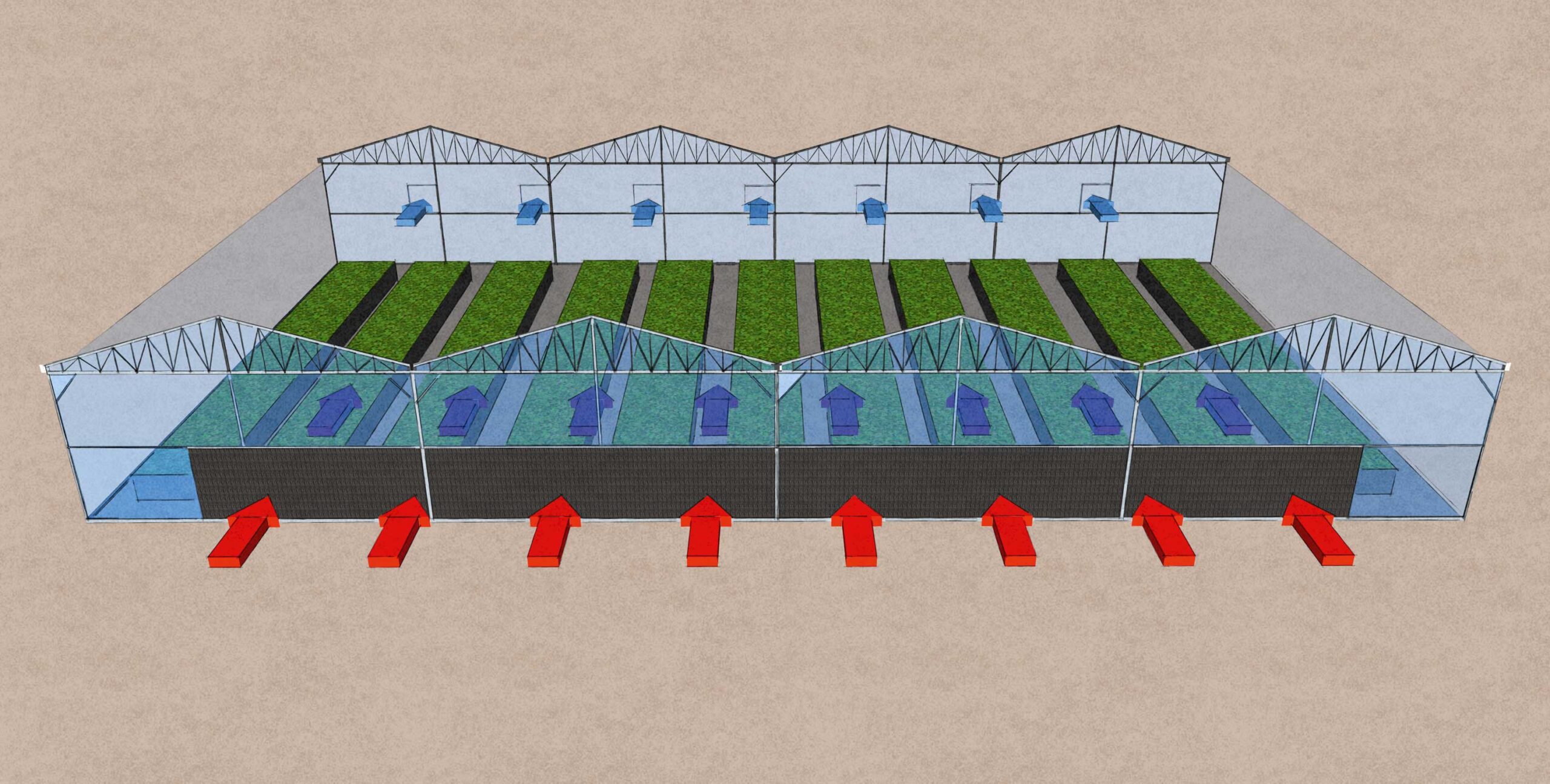

The LUBING evaporative cooling Pad-System is used in systems where humidification and cooling is required. It can be used for many different cooling purposes but is particularly suitable for evaporative cooling in greenhouses.

OVERVIEW | ADVANTAGES | HOW IT WORKS | VIDEOS | COMPONENTS | BENEFITS | DOWNLOADS

OVERVIEW:

The LUBING Pad Climate System is used in areas where highly efficient cooling is required. It can be used for many different cooling purposes.

Water is circulated through the system by a pump station and supplied to the top of the cooling pad via a water distribution pipe and the deflector. The water flows down the corrugated surface of the evaporative cooling pad.

Advantages of the lubing pad system

EASY INSTALLATION

Newly designed clip profiles provide easy installation

NO CORROSION

All parts are made of PVC or stainless steel

No external water tank required

The water gutter provides a finite amount of water to run the system until evaporation losses require additional supply via an automatic float valve

IDEAL WATER DISTRIBUTION

Deflector design with integrated hinge system provides the ideal water distribution over the entire pad length

RODENT PROOF

Newly designed water trough has a rodent-proof cover and provides ideal water recirculation

ROBUST WATER PUMPS

Robust centrifugal water pumps available in different sizes and voltages

HOW IT WORKS:

-

- Water is transported through the system from a pump station and directed onto the pads from above with a water distribution pipe and water deflector.

- The water then flows over the corrugated surface of the pad where it’s surface area is maximized to efficiently remove heat from the air flowing through it, resulting in some evaporation.

- The remaining water is used to clean the pads and flows back to the supply unit via a water channel system.

The thermal energy required for evaporation comes directly from the air. Therefore, the air coming out of the pads is cooled and humidified at the same time without any additional external energy supply for the evaporation process.

VIDEO OVERVIEW

HOW IT WORKS

COMPONENTS:

WATER DISTRIBUTION

-

Special distribution pipes

-

Newly developed deflector

-

Even water distribution over the entire pad length

Ball valves

- 2“ ball valve in-line for fine -adjustment of water quantity

- 1“ ball valve (T-piece) for -adjustment of permanent -water drain (bleed-off)

Deflector

- Newly developed deflector -profile with integrated hinge system

- Easy access, quick inspection and easier cleaning

Clip function

- All profiles with clip function for easy attachment to the -pipe holder

- Pad guides provide high stability

- Easy exchange of pads

Water gutter

- Water gutter for complete water demand of the system – no external water tank necessary

- Holder for securing the water -gutter to the wall or floor

Supply unit

- Delivers completely assembled

- Included integrated flushing adapter for thorough flushing of the system

- Float valve maintains constant water level in the system by controlling incoming water supply

Water pumps

- Centrifugal pumps with integrated filter and 2“ pipes

- Pumps available in three different sizes and voltages to suit your required system length (see back side)

Water gutter cover

- Pad supports provide ideal water recirculation

- Rodent proof

- Optional splash protection profile available

THE BENEFITS OF LUBING’S PLASTIC PADS:

- Excellent cooling capacity – patented design: The special layout of solid surfaces and mesh structures ensures ideal water distribution through the Pad. This allows for proper wetting and less splashing, resulting in highly efficient cooling capacity

- Easy to clean: The use of welded, highly resistant polymer sheets allows the plastic pad to be easily cleaned without damaging the Pads

- Long service life: The use of polymer sheets in combination with thermal welding guarantees best stability and a long service life

- Lowest pressure loss: At an air velocity of 300 ft/min (1.5 m/s) the plastic pad’s pressure drop is only at 0.40 inches of water (10 Pa.) substantially lowering energy consumption

- High UV resistance: The use of UV-stabilizing additives ensures outstanding resistance to UV light for years.

- Impermeable to light: The plastic pad’s geometry blocks out light from the outside

- Chemical resistance: The plastic pad is made of Polypropylene, which is highly resistant to most chemicals.

- Pad width: Pads are offered in 2’ wide sections

DOWNLOADS

PRODUCT LITERATURE

Manuals/Technical Documents

LUBING Systems, L.P.

135 Corporate Dr, SW

Cleveland, TN 37311

P: 205-902-3478

General Information:

customerservice@lubingusa.com

Technical Support:

engineering@lubingusa.com